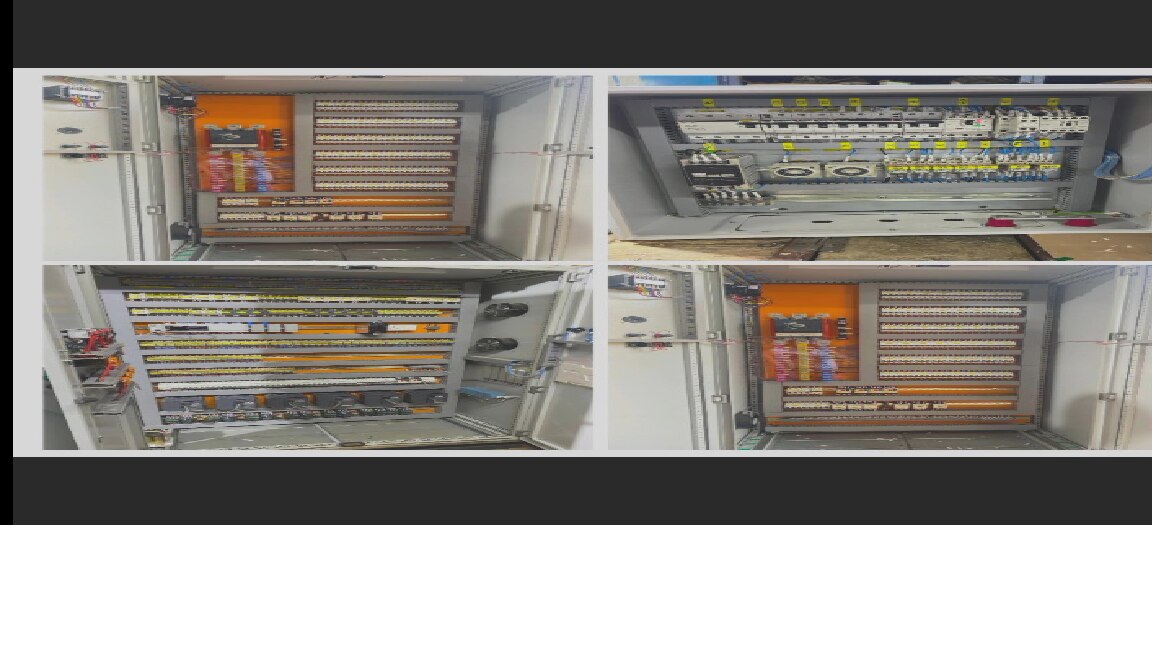

🧠 PLC System:

This panel is designed for modern programmable logic controllers like Siemens S7-1200, Allen-Bradley CompactLogix, or Delta PLCs.

🖥️ HMI Interface:

It includes an HMI such as Siemens KTP700 or Weintek, providing a touchscreen interface for operators.

🏭 Application Scope:

Suitable for industries such as manufacturing, packaging, water treatment, or chemical processing.

🔌 Power Supply & I/O:

Operates on 24VDC or 230VAC and supports both digital and analog I/O modules for field device integration.

📛 Header Panel:

Displays machine name, real-time clock 🕒, and connection status 🔄 at the top of the HMI screen.

📈 Live Process Data:

Shows real-time values for temperature 🌡️, pressure , flow 💧, and tank level 📏.

🤖 Auto/Manual Control:

Operators can switch between automatic PLC control and manual operation modes.

⏯️ Start/Stop Functions:

Includes dedicated buttons for 🟢 Start, 🔴 Stop, and 🔁 Reset to manage machine operation.

🚦 Status Indicators:

Shows machine conditions such as 🟢 Running, 🟡 Idle, 🔴 Stopped, ⚠️ Fault, and 🔧 Maintenance.

🔔 Alarm Notifications:

Visual and audible alerts appear for faults, safety trips, or abnormal conditions.

📊 Trend Graphs:

Displays historical data charts for key variables like temperature and pressure over time.

🔢 Production Counter:

Tracks output in units or batches, resettable per shift or production cycle.

🛠️ Maintenance Alerts:

Provides service reminders based on runtime or calendar schedules, with countdown timers.

📡 Communication Status:

Indicates the health of connections with protocols like 🧬 Modbus, 🌎 Ethernet/IP, and 🔌 Profibus.

🗺️ Mimic Diagram:

A graphical layout of the system includes animated symbols (🔄 motors, 🧯 valves, 🚰 pumps) for interaction.

👁️🗨️ User Interface Design:

Uses a clean industrial design with high-contrast visuals, ISA symbols, and touch-friendly buttons.

🈳 Multilingual Support:

Interface can switch languages (e.g., English, Arabic, Spanish) for operator convenience.

📐 Unit Customization:

Supports different engineering units such as °C/°F, bar/psi, and LPM/GPM based on user needs.

🧭 Summary:

This panel provides full monitoring, control, diagnostics, and alerts—ensuring operational safety, reliability, and efficiency.